Glass Lined Distillation Tank

Our company's glass lined distillation tank is produced by making high content silica into high-quality corrosion-resistant enamel glaze, and spray the glaze on the surface of the metal matrix. The glaze will be closely adherent to the surface of the metal after a high-temperature firing of 950℃. Therefore, possessing the dual nature that combines the corrosion resistance of glass and the strength of metal, it is good corrosion resistant equipment. Now, it has been widely applied in industries and departments, such as petroleum, chemicals, light industries, medicines, agriculture, pharmaceuticals, foods, fuels, and scientific research.

Corrosion resistance of distillation tank: it is resistant to the corrosions of inorganic acids, organic acids, organic solvents and weak alkalis in all concentrations (except for hydrofluoric acids, media that contain fluoride ion, and concentrated phosphoric acids and strong alkalis with a concentration ≥30% and a temperature ≥180℃).

Standard:HG/T3126-1998

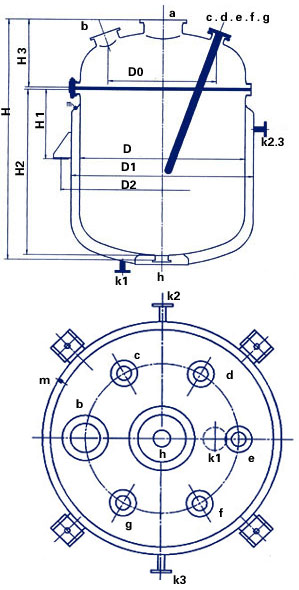

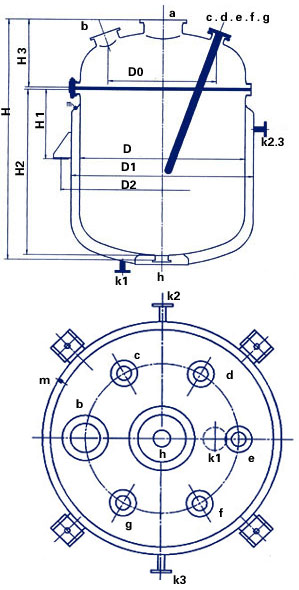

Overall Dimensions and Nozzle Sizes of Glass Lined Distillation Tank

Nominal volume L | Actual volume L | Heat exchange area of jacket (m2) | Sizes (mm) | Nozzle sizes (mm) | Approx

Weight

Kg |

D | D 0 | D 1 | D 2 | H | H1 | H 2 | H3 | a | b | c | dg | ef | h | K

1-3 | m |

K300 | 369 | 1.75 | 800 | 560 | 900 | 1048 | 1280 | 350 | 870 | 390 | 150 | 125 | 70 | 80 | 80 | 80 | 3-25 | 1/2 ″ | 568 |

K500 | 588 | 2.27 | 900 | 630 | 1000 | 1130 | 1504 | 400 | 1070 | 415 | 200 | 150 | 80 | 100 | 80 | 80 | 3-32 | 1/2 ″ | 778 |

K1000 | 1250 | 4.54 | 1200 | 840 | 1300 | 1488 | 1810 | 500 | 1270 | 510 | 300 | 200 | 80 | 100 | 80 | 100 | 3-32 | 1/2 ″ | 1439 |

K1500 | 1720 | 5 | 1300 | 910 | 1450 | 1622 | 2035 | 500 | 1470 | 535 | 300 | 200 | 80 | 100 | 80 | 100 | 3-40 | 1/2 ″ | 1908 |

K2000 | 2280 | 6.42 | 1600 | 1120 | 1750 | 1962 | 1988 | 600 | 1330 | 630 | 400 | 200 | 100 | 125 | 100 | 125 | 3-40 | 1/2 ″ | 2510 |

K3000 | 3380 | 8.67 | 1600 | 1120 | 1750 | 1962 | 2475 | 600 | 1810 | 630 | 400 | 200 | 100 | 125 | 100 | 125 | 3-40 | 1/2 ″ | 3196 |

Main Technical Performance of Glass Lined Distillation Tank

Glass lined

Distillation Tank | Max. Operation Pressure (Mpa) | Operation Temperature (°C) | Glass lining Thickness (mm) | High Voltage Test to Glass Layer (kv) |

Inner of Vessel | Inner of Jacket | Inner of Vessel | Inner of Jacket |

0.25 | 0.6 | 0~200 | 0~200 | 0.8~2.0 | 20 (Retest of User: 6) |

| Remarks:Temperature difference operation limit for glass lining:cooling shock:110°C,thermo shock:120°C. (This is Destructive Test). |